A short guide to making biochar for an economic use

What is biochar?

Pyrolysis process summarised in the burning of a match metaphor1

Biochar is made during a process called pyrolysis where the volatiles are combusted and the remaining material left behind is high in carbon. Biochar can be made from any biomass and it’s preferable if this is a waste of some sort. The resulting porous matrix of solid carbon2 is stable and durable at time scales exceeding hundreds to thousands of years3. It has multiple benefits as a soil amendment and so is fundamentally a permanent improvement in human scale timeframes.

Pyrolysis Methods:

This can be as simple as a pit or trench in the ground to sophisticated and often automated machines.

This kind of pit can be dug with a spade in a location near the biomass4

In between there are various form factors of kilns and retorts. The kontiki kiln is well documented and makes around 1000 litres in an afternoon5.

When the top layer of biomass begins to grey with ash, it is the time to add the next fuel layer. This blocks the air to the lower layers and allows them to char completely6

Kontiki kiln at lighting (done on top to minimise smoke) on left and burning with shield added for safety and efficiency7 on the right.

The Ring of Fire kiln is another option:

This kiln is made from sheets of metal bolted together (fitting into a station wagon) and is large enough (diameter of 2.3m) to be loaded by a machine.

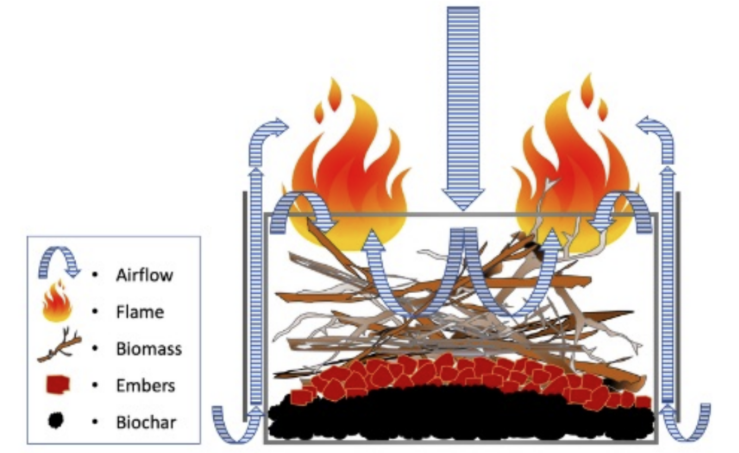

Drawing showing the pre-heated air that enters in such a way to ensure a clean burn8

Or a mobile retort for a batch process - fill the vessels with biomass as well as around in the outside chamber, light, and then wait until it completes (flames finish):

Portability and high quality clean biochar results from a unit such as this9

Residence time and highest treatment temperature (HTT) are critically important characteristics of pyrolysis. In general, HTT of 450° C is the minimum required to achieve the formation of linked ring structures (aromaticity) at the molecular level, making it recalcitrant, and very long lived in the soil. HTT of 600° C is a good benchmark for greatest potential aromaticity and porosity. Temperatures in excess of 750° C start to produce diminishing returns, as the graphene structures begin to fuse into plates and collapse the internal surface area10.

Feedstock form factor is another consideration that will be at least partially dictated by the type of pyrolysis employed. Most continuous process equipment requires incoming material to be chipped or shredded to achieve an optimum average particle size and density factor. Batch retorts can be more tolerant of greater length and diameter pieces, but will need longer HTT treatment time at highest temperature.

Feedstock preparation

For general biochar creation, the most favourable feedstocks are those woody materials that are high in lignin and can include things like forestry slash and debris, sawdust, bark, offcuts and residuals from timber milling, prunings and cullings from horticulture and viticulture, and woody branches and brushy material in the municipal solid waste stream (green organics). These produce a biochar with high surface area and high carbon levels and these attributes make it highly prized for soil amendment, environmental management, and water quality11.

Non-woody components of waste streams are best left for input into the composting process as their resultant biochar properties are lower in stable carbon and higher in mineral (ash) content12.

Quality Control

Cross contamination of feedstock has its risks. Treated lumber and painted wood contain heavy metals such as cadmium and lead and these pose the highest risk to human health and to environment harm. Burning these can lead to the offgassing and escape to the atmosphere of volatile compounds including arsenic, and the resulting biochar could have unacceptably high levels of toxic products bound up in its structure. Biomass contamination with chemical compounds containing chlorine or fluorine can also lead to the formation of toxicants. It is interesting to note that small amounts of non-chlorinated hydrocarbons such as oil or plastics at levels less than 2% by dry weight do not pose a hazard, as the high heat of pyrolysis causes complete thermal decomposition of the polymers13.

For commercial biochar production regular sampling and testing to ascertain the quality of biochar being produced is important. These tests verify that it is within acceptable limits for substances of concern. The International Biochar Initiative publishes assessment categories and protocols for biochar producers14.

References

1 Match image from https://biochar-international.org/about-biochar/how-to-make-biochar/biochar-production-technologies

2 International Biochar Initiative Biochar Standards version 2.1, Section 1 https://biochar-international.org/biochar-standards

3 Rodionov, A., W. Amelung, N. Peinemann, L. Haumaier, X. Zhang, M. Kleber, B. Glaser, I. Urusevskaya, and W. Zech (2010), Black carbon in grassland ecosystems of the world, Global Biogeochem. Cycles, 24, GB3013, https://doi.org/10.1029/2009GB003669

4 https://www.reddit.com/r/Permaculture/comments/ewnxg7/biochar_batch_via_trench_pit_method_ready_to

5 Schmidt, Hans-Peter & Taylor, Paul. (2014). Kon-Tiki flame cap pyrolysis for the democratization of biochar production. Ithaka Journal for biochar materials, ecosystems & agriculture. 1. 338-348.

6 https://www.ithaka-journal.net/en/ct/151-kon-tiki-the-democratization-of-biochar-production

7 https://www.thebiocharrevolution.com/biochar-production-in-kon-tiki-australia

9 https://biocharkilns.com/biochar

10 Lehmann, J., Joseph, S. (2015), Biochar for Environmental Management 2nd Edition, ISBN: 978-0-415-70415-1 p 111-137

11 Lehmann, J., Joseph, S. (2015), Biochar for Environmental Management 2nd Edition, ISBN: 978-0-415-70415-1, p 719

12 Ibid p 719

13 IBI Biochar Standards version 2.1, Section 3.1 (https://biochar-international.org/biochar-standards)

14 IBI Biochar Standards version 2.1, Section 4